Imwe yemabhenefiti makuru ekushanda naYi Zheng ruzivo rwedu rwese system;isu hatisi chete nyanzvi mune chimwe chikamu chemaitiro, asi panzvimbo pezvo, chikamu chese.Izvi zvinotibvumira kupa vatengi vedu maonero akasiyana ekuti chikamu chimwe nechimwe chemaitiro chichashanda sei pamwe chete.

Isu tinogona kupa yakazara granulation masisitimu, kana zvidimbu zvega zvechishandiso zveese inorganic uye organic application.

Yedu disc granulator yekugadzira mutsara inonyanya kugadzira fetireza yekomboni.Kazhinji, fetireza yekomboni ine zvingangoita zviviri zvezvinhu zvitatu zvinovaka muviri (nitrogen, phosphorus, uye potassium).Iine maficha ehukasha hwakanyanya, mashoma mhedzisiro, uye zvakanaka zvemuviri zvimiro, fetireza yekomboni inoita basa rakakosha mukuyeresa fetereza, kuvandudza kushanda kwefetereza uye kusimudzira goho rezvirimwa rakanyanya uye rakagadzikana, tambo yedu yekugadzira fetireza pani granulator inogadzirirwa zvakanyanya. vagadziri vefetereza vane zvakawanda zvinodiwa pakubuda.Mutsetse wekugadzira fetireza uyu unokwanisa kugadzira fetireza yeNPK, DAP nekuisa zvimwe zvinhu kuita zvidimbu zvefetereza.Iyo tekinoroji yekugadzira fetireza chirimwa ichi chepamusoro, inoshanda uye inoshanda.Midziyo yese yefetereza yakamanikana, yakakwira-otomatiki uye iri nyore kushanda, iri nyore pakugadzira fetireza yakawanda.

Advantage:

1.Michina yese yefetereza inoshandisa anti-corrosion & kupfeka-resistant materials.

2. Adjustable simba maererano nezvinodiwa nevatengi.

3. Hapana kurasa tsvina, kuchengetedza simba uye kuderedza kushandiswa, kuchengetedza kwezvakatipoteredza.Kushanda kwakagadzikana, kuri nyore kuchengetedza.

4. Iyi fetireza kugadzirwa mutsetse anogona kubudisa kwete chete mukomboni fetiraiza ane yakakwirira, svikiro, uye yakaderera pfungwa, asi Organic fetiraiza, inorganic fetiraiza, bio fetiraiza uye magnetizing fetiraiza etc. Disc granulator pamwe yakakwirira granulation mwero.

5. Ne compact marongerwo, iyo yakazara seti yekugadzira fetiraiza mutsara ndeyesainzi uye inonzwisisika, uye yepamusoro mune tekinoroji.

7. Wide adaptability of raw materials, akakodzera granulation yemacompound fertilizer, pharmaceuticals, chemicals, feed and other raw materials.

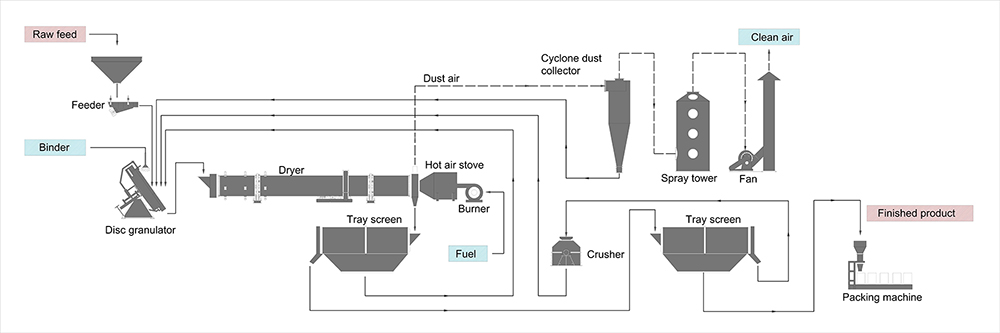

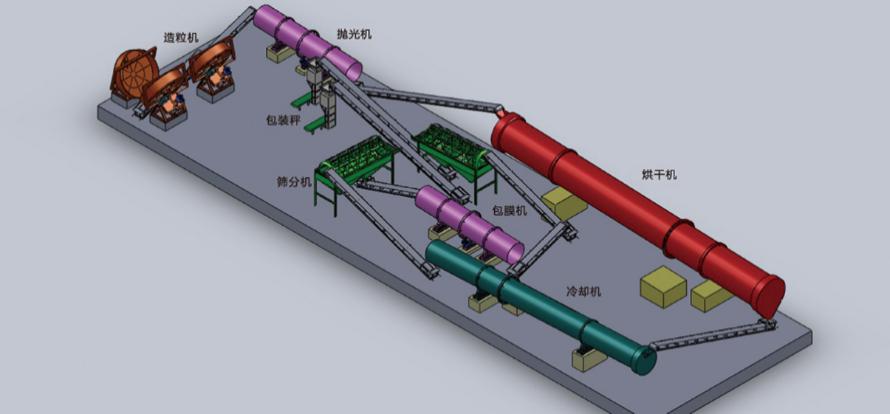

Mutsara wose unosanganisira Disc feeder (kuisa zvinhu mutangi) → Disc mixer (yekuvheyesa zvinhu zvakabikwa)→ cheni inopwanya (yekupwanya)→ Disc granulator (ye granulating)→ rotary drum dryer(yekuomesa) → rotary dhiramu inotonhorera (yekutonhodza) → sikirini yedhiramu inotenderedzwa (yekuongorora zvigadzirwa zvakapedzwa uye zvisina kukodzera)→ imba yekuchengetera zvigadzirwa zvapera (yekuchengetera)→ otomatiki pasuru (yekurongedzerwa)→ chinotakura bhandi→ kamuri yekumisa huruva→ chinotsinhanisa kupisa

CHIZIVISO:Iyi mutsara wekugadzira ndeye yako referensi chete.

Iyo granulation tekinoroji maitiro emusanganiswa wekugadzira fetiraiza mutsara anogona kazhinji kukamurwa kuita:

1.Material Batching Process

Chekutanga, mbishi zvinhu zvakagoverwa mukunyatsoenderana nechikamu.The mbishi zvinhu zvinosanganisira urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, imwe superphosphate, uye coarse whiting), potassium chloride, potassium sulfate uye etc. The yakasimba allocation reshiyo yezvinhu mbishi kuvimbisa yakakwirira yepamusorosoro. fetireza kushanda zvakanaka.

2.Materials Stiring Process

Raw zvinhu zvinosanganiswa pamwechete mu disc mixer iyo inogona kunyangira zvinhu zvakaenzana.

3.Kupwanya Maitiro

Muchina wekupwanya cheni unopwanya zvinhu zvakakura kuita zvidimbu zvidiki izvo zvinogona kusangana nezvinodiwa zvegranulation.Ipapo bhandi rekutakura rinotumira zvinhu kune pan granulator kuti granulate.

4.Granulating Process

Disc fetiraiza granulator inotora arc disc angle chimiro.Iyo granulation rate inogona kusvika pamusoro pe93%, iyo ine imwe yeakanakisa granulation ratios pakati peese mafetereza granulator.Kushandisa iyo inoenderera inopoterera-inotenderera yemidziyo uye yekupfapfaidza mudziyo kutyaira mbishi zvinhu zvichikunguruka mudhisiki.Inogona kuburitsa yunifomu uye yakanaka kutaridzika granules.Pan granulator muchina unonyanya kukosha mumutsetse wekugadzira fetereza.

5.Drying & Cooling Process

Mushure mokunge granulating, granules inoda kuomeswa.Bhandi conveyor kutakura magranules kune inotenderera dhiramu drier.Muchina wekuomesa unobvisa hunyoro kubva kune zvimedu kuti uwedzere kusimba kwemagranules.Saka, yakanakira kuchengetedza.Mushure mekuoma, kutonhora kwegranules kwakakwirira, zviri nyore kuunganidza.Saka isu tinoda kutonhodza magranules nemuchina wekutenderera chigubhu unotonhorera.Mushure mekutonhodzwa, mafetireza granules ari nyore kurongedza, kuchengetedza uye kutakura.

6.Particle Classification Process

Fetereza inofanirwa kuvhenekwa nemuchina we rotary drum screening kana watonhodzwa.Zvigadzirwa zvinokodzera zvinotumirwa mune yakapedzwa chigadzirwa warehouse nebhandi conveyor kana inogona kurongedzwa zvakananga.Magranules asina kukodzera anozodzokororwa zvakare.

7.Product Packing Process

Kurongedza ndiyo yekupedzisira maitiro ekugadzira fetereza mutsetse.Yakazara-otomatiki fetiraiza package inoshandiswa kurongedza zvigadzirwa zvapera.Nepamusoro-otomatiki uye nepamusoro-kushanda, haingogone chete kuyera kuyera, asi inoita yekupedzisira tekiniki maitiro zvakanakisa.Vatengi vanogona kudzora kumhanya kwekudya uye kuseta iyo yekumhanyisa parameter zvinoenderana nezvinodiwa chaizvo.

Nguva yekutumira: Sep-27-2020