Ikuunzwa kweCompound Fertilizer Production Line

Compound Fertilizer ndiyo fetireza ine mbiri kana zvitatu zvinovaka muviri zveN, P;K. Compound fertilizer inowanikwa muhupfu kana granular form.Inowanzo shandiswa se topdressing uye inogona zvakare kushandiswa semupfudze wepasi uye mhodzi yemhodzi.Compound fertilizer ine yakakwirira inoshanda zvikamu, saka inonyungudika nyore nyore mumvura, inoora nekukurumidza, uye inotorwa nyore nyore nemidzi yemidzi, saka inonzi "quick-acting fertilizer".Basa rayo nderekuzadzisa zvinodiwa zvakakwana uye kuenzanisa kudya kwakasiyana kunodiwa nembesa pasi pemamiriro akasiyana.

Mutsara wekugadzira fetireza uyu unonyanya kushandiswa kugadzira mafetereza emusanganiswa uchishandisa zvinhu zveNPK, GSSP, SSP, granulated potassium sulphate, sulfuric acid, ammonium nitrate, nezvimwe.Mudziyo wefetereza wemukomboni une zvakanakira kumhanya wakatsiga, kusashanda zvakanaka kwakaderera, kugadzirisa kudiki uye mutengo wakaderera.

Mutsetse wese wekugadzira wakashongedzerwa nemichina yepamberi uye inoshanda, iyo inogona kuwana gore negore kubuda kwe50,000 matani efotereza yekomboni.Zvinoenderana nezvinodiwa chaizvo zvekugadzira, tinoronga nekugadzira mitsara yekugadzira fetereza ine akasiyana epagore e10,000 ~ 300,000 matani.Iyo yese seti yemidziyo ndeye compact, inonzwisisika, sainzi, yakagadzikana kushanda, kuchengetedza simba, yakaderera mutengo wekugadzirisa, nyore kushanda, ndiyo yakanakisa sarudzo kune komputa vagadziri vefetereza.

Mutsetse wekugadzira fetereza yepakati nepakati

Iyo nzira yekugadzira fetireza mutsara inogona kukamurwa kuita: mbishi zvinhu batching, kusanganisa, kupwanya, granulating, yekutanga kuongorora, granule kuomesa uye kutonhora, yechipiri kuongorora, granule coating uye kuwanda kurongedza.

1. Raw materials batching: maererano nemusika kudiwa uye nharaunda kutsunga ivhu migumisiro, mbishi zvinhu zvakadai urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, general calcium) uye potassium chloride ( potassium sulphate) ichagoverwa mune imwe chikamu.Izvo zvinowedzera uye zvinotsvaga zvinhu zvinoyerwa nechiyero chebhanhire uye zvakaenzaniswa kune imwe chikamu.Zvinoenderana neformula reshiyo, zvese zvigadzirwa zvakasanganiswa zvakasanganiswa nemusanganisi.Iyi nzira inonzi premix.Iyo inovimbisa kuumbwa kwakaringana uye inogonesa inoshanda uye inoenderera batching.

2. Kusanganisa: Sanganisa zvakakwana zvinhu zvakagadzirirwa zvakagadzirirwa uye uzvikurungadze zvakaenzana, izvo zvinoisa hwaro hwehunobudirira uye hwepamusoro-soro granular fertilizer.Yakachinjika musanganiswa kana disc musanganiswa inogona kushandiswa kunyange kusanganisa.

3. Kupwanya: Kupwanya caking muzvinhu zvakakosha kune inotevera granulation processing.Chain crusher inonyanya kushandiswa.

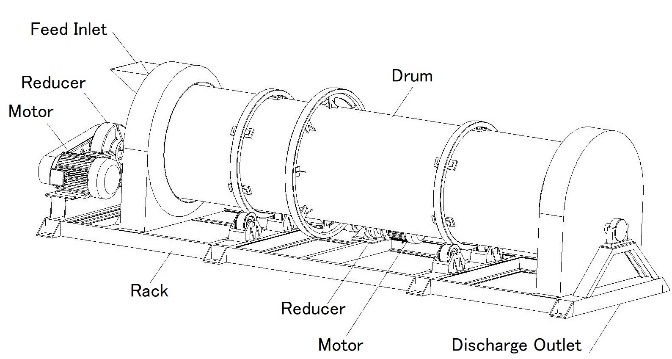

4. Granulating: Izvo zvakaenzana zvakanyandurwa uye zvakapwanyika zvinhu zvinotakurwa kune granulator kuburikidza nebhandi conveyor ye granulating, iyo ndiyo chikamu chepakati chemutsara wose wekugadzira.Sarudzo yegranulator yakakosha, isu tine disc granulator, rotary dhiramu granulator, roller extrusion granulator kana komputa fetiraiza granulator yesarudzo.

5. Kuongorora kwepuraimari: Tora preliminary screening for granules, uye dzorera vasina kukodzera pakupwanya kuti vagadzirise zvakare.Kazhinji, iyo rotary yekuongorora muchina inoshandiswa.

6. Kuomesa: Magranules akakodzera mushure mekuongororwa kwekutanga anotakurwa nebhandi conveyor kune rotary dryer kuti aomese kuderedza hunyoro hwemagranules apera.Mushure mekuoma, hunyoro hwemagranules huchadzikira kubva pa20% -30% kusvika 2% -5%.

7. Granules kutonhora: Mushure mekuoma, magranules anotumirwa kune inotonhorera kuti itonhorere, iyo yakabatana neinoomesa nebhanhire rekutakura.Iko kutonhora kunogona kubvisa guruva, kunatsiridza kutonhora kwakanaka uye kupisa kushandiswa kwechiyero, uye kuwedzera kubvisa mwando mufetereza.

8. Chechipiri chekuongorora: Mushure mekutonhodzwa, ese asina kukodzera granules anotariswa kunze kuburikidza neinotenderera yekuongorora muchina uye anotakurwa nebhandi conveyor kumusanganisi uye obva asanganiswa nezvimwe mbishi zvekugadzirisa zvakare.Zvigadzirwa zvakapedzwa zvichaendeswa kumushini wekuputira fetireza.

9. Kuvhara: Inonyanya kushandiswa kupfekedza pamusoro pe-quasi-granules nefirimu yekudzivirira yunifomu kuti ibudirire kuwedzera nguva yekuchengetedza uye kuita kuti granules iwedzere.Mushure mekuputira, heino huya kune yekupedzisira maitiro - kurongedza.

10. Packaging system: Automatic quantitative packaging machine inogamuchirwa mune izvi.Muchina uyu unoumbwa neotomatiki kuyera uye kurongedza muchina, yekufambisa sisitimu, yekuisa chisimbiso muchina uye zvichingodaro.Hopper inogonawo kugadzirwa zvinoenderana nezvinodiwa nevatengi.Quantitative kurongedza kwezvinhu zvakawanda senge organic fetireza uye komputa fetireza yakashandiswa zvakanyanya mukushandiswa mumaindasitiri akasiyana neminda.

Tekinoroji uye Zvimiro zvemutsetse wekugadzira fetereza yakasanganiswa:

Rotary drum granulator inonyanya kushandiswa mukugadzira yakakwirira-concentration compound fetereza tekinoroji, disc non-steam granulator inogona kushandiswa mukugadzira yakakwirira, yepakati uye yakaderera kusanganiswa kwekomboni fetireza tekinoroji, yakasanganiswa neiyo anti-caking tekinoroji, yakakwira nitrogen. tekinoroji yekugadzira fetereza yemubatanidzwa nezvimwe zvakadaro.Mutsetse wedu wekugadzira fetereza wemukomboni une zvinotevera:

1. Kushandiswa kwakakura kwezvinhu zvakabikwa: mafetireza akasanganiswa anogona kugadzirwa zvinoenderana neakasiyana magadzirirwo uye zviyero, uye akakodzerawo kugadzirwa kwe organic uye inorganic compound fetereza.

2. High pellet-forming rate uye chiyero chekupona kwehutachiona hwehutachiona: tekinoroji nyowani inogona kuita kuti pellet-forming rate isvike 90% ~ 95%, uye tekinoroji yakadzika uye yekuomesa mhepo inogona kuita kuti huwandu hwehupenyu hwehutachiona huve hutachiona. kusvika 90%.Chigadzirwa chakapedzwa chakanaka pakuonekwa uye yunifomu muhukuru, 90% ayo ari magranules ane saizi ye2 ~ 4mm.

3. Flexible process flow: The process flow of compound fertilizer production line inogona kugadziriswa zvichienderana nechaiyo mbishi zvinhu, formula uye saiti, uye customized process flow inogonawo kugadzirwa zvinoenderana nezvinodiwa chaizvo.

4. Yakagadzikana yehuwandu hwehuwandu hwezvigadzirwa zvakapedzwa: kuburikidza neotomatiki metering yezvigadzirwa, metering yakarurama yemarudzi ose emhando dzakasimba, mvura uye zvimwe zvinhu zvakasvibirira, zvakada kuchengetedza kugadzikana uye kushanda kwezvose zvinovaka muviri muhutano hwose.

Compound Fertilizer Production LineApplications

1.Sulfur coated urea production process.

2.Kusiyana kwemhando ye organic uye inorganic fertilizer process.

3.Acid compound fertilizer granulation process.

4.Powdery industrial waste inorganic fertilizer process.

5.Large particle urea production process.

6.Seedling Substrate kugadzira fetereza.

Nguva yekutumira: Sep-27-2020