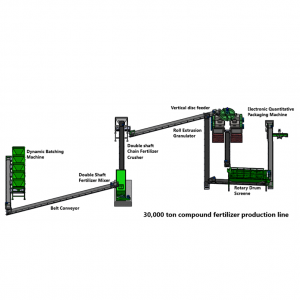

Compound fertilizer granulation production line.

Thedisc granulation yekugadzira mutsarainogona kushandiswa kugadziramusanganiswa fetereza.Kazhinji, fetiraiza yekomboni ine zvingangoita zviviri kana zvitatu zvinovaka muviri (nitrogen, phosphorus, potassium).Iine maitiro ehuwandu hwehuwandu hwekudya uye hushoma mhedzisiro.

Compound feterezainoita basa rinokosha pakuberekesa kwakadzikama.Haikwanisi chete kuvandudza kushanda kwefetireza, asiwo kukurudzira kugadzikana uye goho guru rezvirimwa.Iyo disc granulator yekugadzira mutsara ndiyo yakanaka mhinduro yekuwana yakakwirira mhando uye yakakwirira chibereko checompound fertilizer.Mutsetse wekugadzira uyu unogona kugadzira fetireza yeNPK, fetireza yeDAP uye mamwe mafotereza emukomboni.

Work Principle :

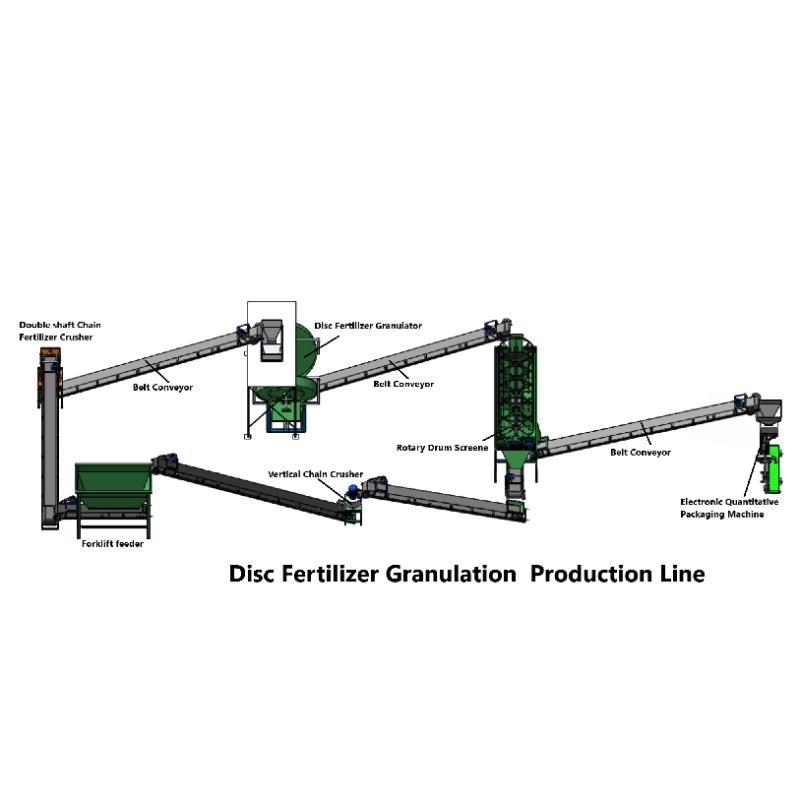

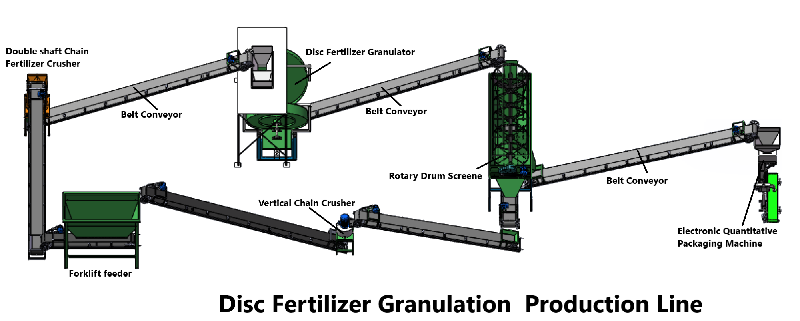

Iyo yekugadzira mutsara michina yedhisiki granulator inosanganisira yekuchengetera zvinhu → musanganiswa (musanganiswa) → disk granulator (granulator) → dhiramu sieve muchina (kusiyanisa pakati pezvigadzirwa zvepasi uye zvigadzirwa zvakapedzwa) → vertical cheni crusher (kutyora) → otomatiki yekurongedza muchina (kurongedza) → belt conveyor (kubatanidzwa kwemaitiro akasiyana-siyana) nemimwe michina.Cherechedza: iyi mutsara wekugadzira ndeyekutarisa chete.

Iyo nzira yekuyerera yedhisiki granulator yekugadzira mutsara inogona kukamurwa kuita:

1. Raw material ingredients process

Chekutanga, govera mbishi zvinhu zvakanyatsoenderana.Raw zvinhu zvinosanganisira urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (ammonium phosphate, diammonium phosphate, calcium monophosphate, calcium carbonate), potassium chloride, potassium sulfate, etc. Strict raw material ratio inogona kuvimbisa kushanda kwefetereza yakakwirira.

2. Raw material mixing process

Zvose zvakasvibiswa zvinosanganiswa uye zvinosanganiswa zvakafanana mu blender.

3. Yakaputsika nzira

Iyo yakatwasuka ketani crusher inopwanya zvidimbu zvihombe zvezvinhu kuita zvidimbu zvidiki zvinogona kusangana nezvinodiwa granulation.Ipapo bhandi rekutakura rinotumira zvinhu mudhisiki granulation muchina.

4. Granulation process

Iyo dhisiki angle yemuchina wedhisiki granulation inotora arc chimiro, uye chiyero chekugadzira bhora chinogona kusvika kupfuura 93%.Mushure mekunge zvinhu zvapinda muplate yegranulation, kuburikidza nekutenderera kunoramba kuripo kwegranulation disk uye chigadziro chekupfapfaidza, zvinyorwa zvinosungirirwa zvakaenzana pamwe chete kuti zvibudise zvimedu zvine chimiro chakafanana uye chimiro chakanaka.Disk granulator chinhu chakakosha pamutsara wekugadzira wefotereza yakasanganiswa.

5. Kuongorora maitiro

Iyo yakatonhodzwa zvinhu inotakurwa kumushini we roller sieve kuti iongororwe.Zvigadzirwa zvinokodzera zvinogona kupinda mudura rakapedzwa kuburikidza nebhandi rekutakura, uye zvakare rinogona kurongedzerwa zvakananga.Zvimedu zvisina kukodzera zvichadzokera kune regrainate.

6. Packaging process

Packaging ndiyo yekupedzisira nzira yekugadzira fetireza yekomboni.Chigadzirwa chakapedzwa chakapetwa nemuchina wekuzadza otomatiki wehuwandu.Iyo yakakwira dhigirii ye otomatiki uye yakanyanya kushanda zvakanaka haingoite kuyera kwakaringana, asiwo zvakanakisa kupedzisa maitiro ekupedzisira.Vashandisi vanogona kudzora kumhanya kwekudya uye kuseta iyo yekumhanyisa paramita zvinoenderana nezvinodiwa chaizvo.

Mutsara wekugadzira fetireza granulationiri kutsvaga Yizheng Heavy Industries, mutengesi ane hunyanzvi, nzvimbo yekutengesa, yakagadzikana mashandiro echigadzirwa, uye vimbiso yemhando.Inopa ayakazara seti yemitsara yekugadzira fetiraizamupfudze wehuku, mupfudze wenguruve, mupfudze wemombe, uye mupfudze wemakwai une goho repagore rematani 10 000 kusvika ku200 000.Chimiro chekugadzira.

Kuti uwane mamwe akadzama mhinduro kana zvigadzirwa, ndapota teerera kune yedu yepamutemo webhusaiti:

https://www.yz-mac.com/disc-granulation-production-lineb/