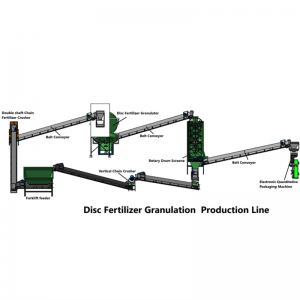

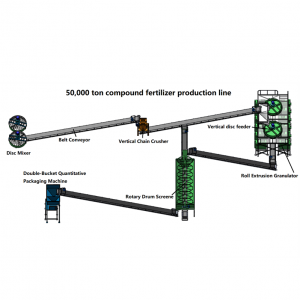

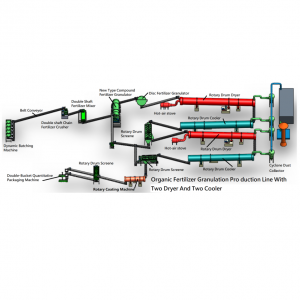

Compound fertilizer granulation production line

musanganiswa wekugadzira fetireza granulation line.

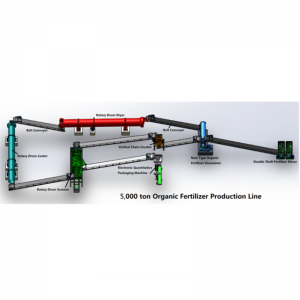

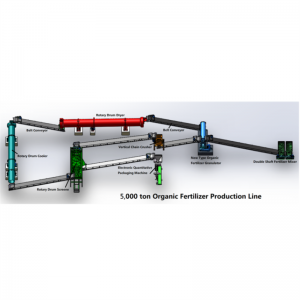

Yizheng Heavy Indasitiri inoshanda mukushandisa marudzi ese eorganic fertilizer kugadzira line michina, mutsetse wekugadzira fetireza, uye inogona kupa seti yakakwana yezvigadzirwa zve organic fetiraiza, organic fetireza granulator zvishandiso, organic fetireza yekuchinjisa muchina, fetiraiza kugadzira michina uye zvimwe zvakakwana kugadzira michina.

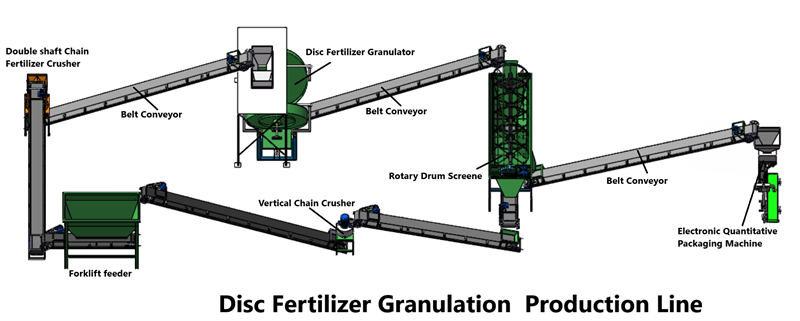

Thedisc granulation yekugadzira mutsarainogona kushandiswa kugadzira fetereza yakasanganiswa.Kazhinji, fetiraiza yekomboni ine zvingangoita zviviri kana zvitatu zvinovaka muviri (nitrogen, phosphorus, potassium).Iine maitiro ehuwandu hwehuwandu hwekudya uye hushoma mhedzisiro.

Compound feterezainoita basa rinokosha pakuberekesa kwakadzikama.Haikwanisi chete kuvandudza kushanda kwefetireza, asiwo kukurudzira kugadzikana uye goho guru rezvirimwa.Iyo disc granulator yekugadzira mutsara ndiyo yakanaka mhinduro yekuwana yakakwirira mhando uye yakakwirira chibereko checompound fertilizer.Mutsetse wekugadzira uyu unogona kugadzira fetireza yeNPK, fetireza yeDAP uye mamwe mafotereza emukomboni.

The process flow ofdhisiki granulation yekugadzira mutsarakazhinji inogona kukamurwa kuva:

1. Raw material ingredients process

Strict raw material ratio inogona kuita kuti fetereza ishande zvakanaka.Zvigadzirwa zvinosanganisira tsvina yemhuka, michero yakaora, masvuura, miriwo yakasvibira, fetireza yegirini, fetireza yegungwa, fetireza yepurazi, tsvina nhatu, tupukanana nezvimwe zvinhu zvinoraswa nemarara.

2. Raw material mixing process

Zvose zvakasvibiswa zvinosanganiswa uye zvinosanganiswa zvakafanana mu blender.

3. Yakaputsika nzira

Iyo yakatwasuka ketani crusher inopwanya zvidimbu zvihombe zvezvinhu kuita zvidimbu zvidiki zvinogona kusangana nezvinodiwa granulation.Ipapo bhandi rekutakura rinotumira zvinhu mudhisiki granulation muchina.

4. Granulation process

Iyo dhisiki angle yemuchina wedhisiki granulation inotora arc chimiro, uye chiyero chekugadzira bhora chinogona kusvika kupfuura 93%.Mushure mekunge zvinhu zvapinda muplate yegranulation, kuburikidza nekutenderera kunoramba kuripo kwegranulation disk uye chigadziro chekupfapfaidza, zvinyorwa zvinosungirirwa zvakaenzana pamwe chete kuti zvibudise zvimedu zvine chimiro chakafanana uye chimiro chakanaka.

5. Kuongorora maitiro

Iyo yakatonhodzwa zvinhu inotakurwa kumushini we roller sieve kuti iongororwe.Zvigadzirwa zvinokodzera zvinogona kupinda mudura rakapedzwa kuburikidza nebhandi rekutakura, uye zvakare rinogona kurongedzerwa zvakananga.Zvimedu zvisina kukodzera zvichadzokera kune regrainate.

6. Packaging process

Packaging ndiyo yekupedzisira maitiro ekugadzira organic fetireza mutsara.Chigadzirwa chakapedzwa chakapetwa nemuchina wekuzadza otomatiki wehuwandu.Iyo yakakwira dhigirii ye otomatiki uye yakanyanya kushanda zvakanaka haingoite kuyera kwakaringana, asiwo zvakanakisa kupedzisa maitiro ekupedzisira.Vashandisi vanogona kudzora kumhanya kwekudya uye kuseta iyo yekumhanyisa paramita zvinoenderana nezvinodiwa chaizvo.

Kuti uwane mamwe akadzama mhinduro kana zvigadzirwa, ndapota teerera kune yedu yepamutemo webhusaiti:

https://www.yz-mac.com/disc-granulation-production-lineb/